Introduction to Electrowetting

Gabriel Lippmann first published his work on electrocapillarity, the basis of modern electrowetting on dielectric, in 1875[1]. Lippmann observed that the meniscus of mercury in a capillary tube could be modified with the application of a small electric potential.[2] It was found that the same process could not be performed with water as, upon application of a potential difference across electrodes submerged in water, electrolysis occurs.

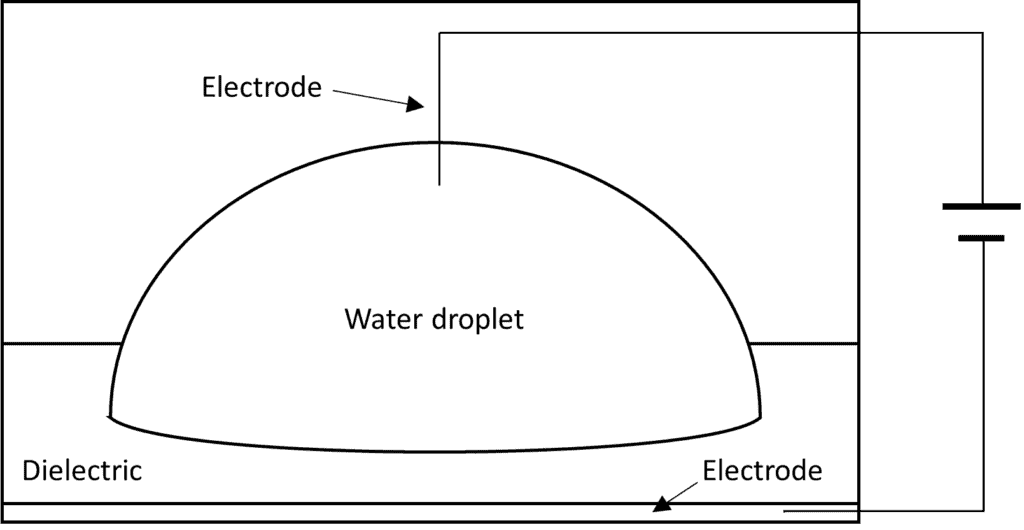

The advancement of electrowetting came with the introduction of a dielectric material to separate the water from one of the electrodes[3]. A water droplet is disposed on, for example, a dielectric film and, on application of a voltage across the droplet and film, flattening of the water droplet occurs. The below figure shows a schematic diagram of an electrowetting on dielectric setup.

Figure 1 – A schematic diagram of an electrowetting on dielectric setup. A water droplet is disposed on a dielectric film.

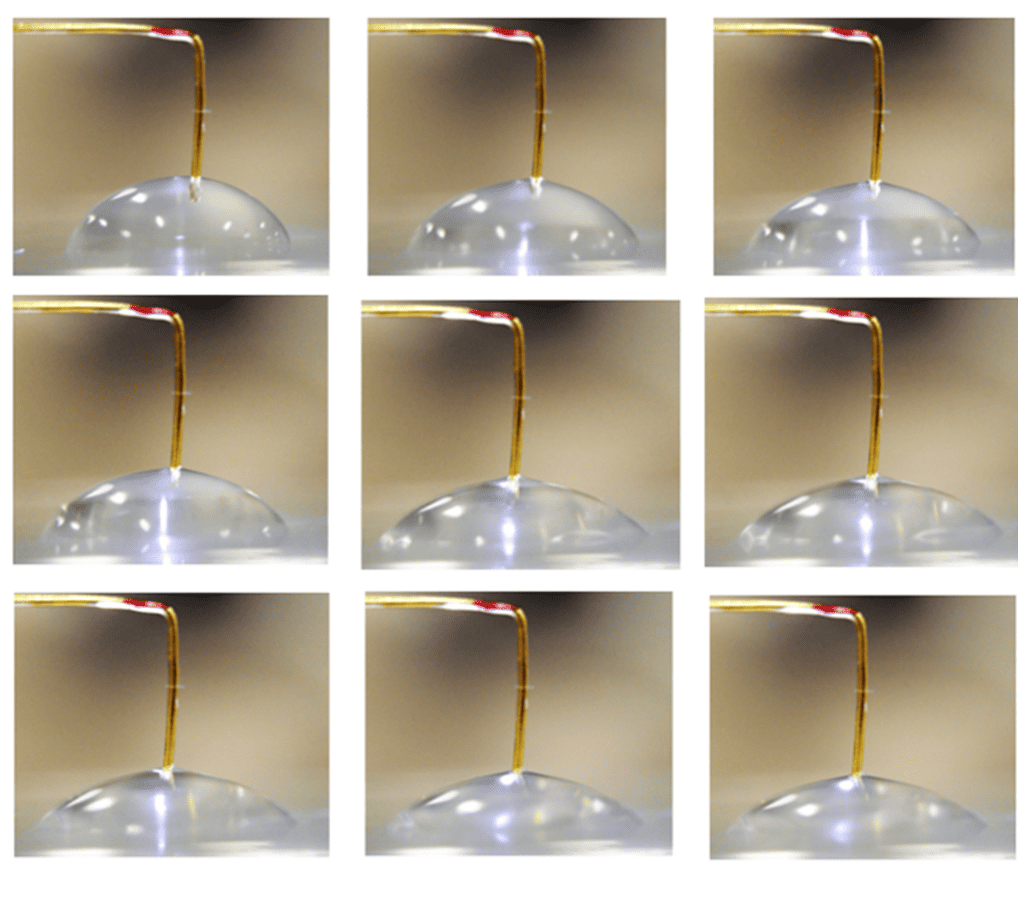

The flattening of the water droplet can be substantial, as shown in the below sequence of images. The top left image shows the application of 0 volts while the bottom right image shows a 5000 volt potential difference across the electrodes.

Figure 2 – A sequence of images showing the electrowetting effect, taken during my research into the application of electrowetting as a liquid lens.

Applications and patents for electrowetting devices

The term electrowetting is attributed to G. Beni and S. Hackwood who, in 1981, used the phenomena to propose a new type of display device. Beni and Hackwood were named inventors on US patent US4417786A, issued 29 September 1983, for their invention titled “Devices based on surface tension changes”. The patent was directed towards “A new class of devices that undergo an optical change upon application of an electrical field and that have desirable stability based on the modification of the surface tension interaction between materials.”

Since the issue of Beni and Hackwood’s patent 40 years ago, many of the major tech companies such as Apple, Samsung and Amazon have filed patents related to electrowetting displays. For example, Samsung Display Co Ltd was granted KR 20120117229 A in 2017 entitled “Electrowetting display”. The Samsung patent sets out the advantages of an electrowetting display over conventional screens as, “Since the electro-wet display device does not use a polarizing plate, it has an advantage of excellent light transmission and reflection efficiency, low power consumption, and fast response speed.”

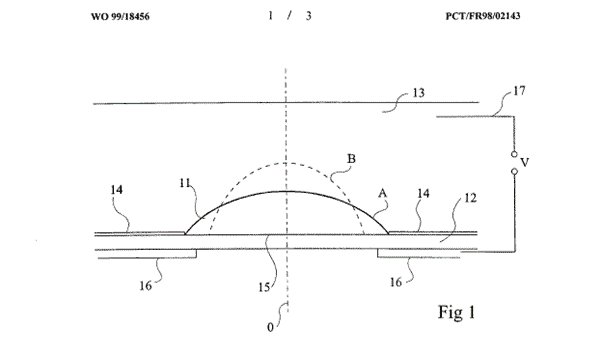

Electrowetting has also precipitated the development of new, promising liquid lens technologies.[4] This technology has the advantage over solid lenses as there are no mechanical parts, therefore eliminating the chance of mechanical failure and reducing the lens’ footprint, making it suitable for use in technology miniaturization.[5] Amongst the first patent applications to mention the application of electrowetting to liquid lenses is WO9918456A1, entitled “LENS WITH VARIABLE FOCUS”. The patent is directed towards “providing a lens whose focal length can vary continuously as a function of an electrical command, by using the phenomenon of electrowetting”.

Figure 3, taken from WO9918456A1, shows a simplified cross-section of the liquid lens. The description describes the figure: “ A drop of an insulating liquid 11 is placed on the inner surface of a wall of a dielectric enclosure 12 filled with a conductive liquid 13. The insulating liquid 11 and the conductive liquid 13 are both transparent, immiscible, have different optical indices and have substantially the same density…When a voltage V is established between electrodes 16 and 17, an electric field is created which, according to the principle of electrowetting mentioned above, will increase the wettability of zone 15 with respect to conductive liquid 13. As a result, the conductive liquid 13 moves and deforms the drop of insulating liquid 11. A variation of the focal length of the lens is thus obtained.”

Conclusion

Although the physics underlying the principle of electrowetting are set by the laws of nature and are unchanging, the innovation and application of the phenomenon has been vast and varied. It will be exciting to see new advances and implementations of this technology.

[1] Lippmann, G. (1875) Relations entre les phénomènes électriques et capillaires. Gauthier-Villars.

[2]Ibid.

[3] Berge, B. (1993) ‘Electrocapillarité et mouillage de films isolants par l’eau’, Comptes rendus de l’Académie des sciences. Série 2, Mécanique, Physique, Chimie, Sciences de l’univers, Sciences de la Terre, 317(2), pp. 157-163.http://www.varioptic.com/media/uploads/publication/variable_focal_lens.pdf

[4] Kang, M. and Yue, R. (2012) ‘Variable-focus liquid lens based on EWOD’, Journal of Adhesion Science and Technology, 26(12-17), pp. 1941-1946.

[5] Deladi, S., Suijver, J., Shi, Y., Shahzad, K., De Boer, B., Rademakers, A., Van Der Vleuten, C., Jankovic, L., Bongers, E. and Harks, E. (2010) ‘Miniaturized ultrasound scanner by electrowetting’, Applied Physics Letters, 97(6), pp. 064102.