Sniffer Doge

The latest developments in the now 9-year long saga of a discarded Hard Drive containing 8000 Bitcoin (or roughly 2.5 billion Dogecoin for adopters of a rival, Shiba-Inu-faced alt-coin) involves plans to search a Welsh landfill site using mechanical arms to pick through the rubbish and robotic dogs to scan the rubbish-heap with cameras (rather than to ward off potential light-fingered data-poachers – to my disappointment). Backed by £10m in hedge fund assets, the infamous James Howells plans to use data recovery experts to extract his fortune from the recovered disk – should it ever be found.

In the infancy of electronic storage, even removing the Hard Drive from the rest of the computer took considerable effort. Had James’ Bitcoins been physically bound to the rest of his system, perhaps throwing them away might have taken additional, physical effort, and provided him with a moment to consider checking if there was anything he was accidentally disposing of.

Should James consider a rather inventive way of trawling through the trash and detecting a drive amongst the detritus, I know a few good patent attorneys.

The Winchester

Systems such as the RAMAC 350 (as discussed in one of my earlier articles) included a plurality of removable disks which could be loaded and replaced. These large, unwieldy metal slabs were housed in permanent, desk-sized structures meaning that there was no real possibility of quickly swapping out different disks – a far cry from now standardised SATA or USB cables.

One of the biggest steps along the HDD evolution timeline came with the transition towards sealed drives – composed of fixed, non-removable transducer heads and disks. Since fixed components may be packaged closer together, by omission of disk loading/unloading mechanisms, or simply not needing to account for space for a person to interact with the disks, this iteration of drives resulted in increased storage density.

In 1973, IBM introduced the IBM 3340 data module, a drive having 30 MB of non-removable storage as well as 30 MB of removable storage. These sorts of drives used a storage technology nicknamed “Winchester”, derived from the once popular Winchester 30-30 rifle. The Winchester name stuck, and now typically refers to drives containing only non-removable storage.

On the Right Track

Besides physical evolution of Hard Drive components, methods were devised for avoiding defects on the disk surface during write operations.

Early examples included allocating data destined for one track to a different track should a defect be detected. This method is particularly wasteful in that entire tracks of data could go unused, despite a defect existing across only a small track portion.

Another example includes splitting a track into smaller sections, known as “records”. Where a defect is detected in one record of a given track, data that would have otherwise been written there is written to a “reserve record” instead, this being part of the track reserved for use in such a circumstance. However, this method requires that each track has a reserve record which may never be used if a defect is not present, but which must always be provided, ultimately reducing usable capacity.

The method of US Patent 3,997,876 provides a dynamic and efficient way of reducing errors during the reading of data on the disk, by effectively making only certain areas of the disk transparent to the read head.

While the disk is first being initialised, the method accounts for defects on the disk surface by detecting a portion of the disk which contains a defect and marking that portion with a “special gap”. The special gap indicates that data read from this region should not be interpreted as valid information. In this case, the tracks include records, storing user data, and “control fields” containing control data. The control data may include the record ID, for example. Importantly, part of the control data is a “skip displacement” field which provides an indication of a distance to an upcoming, known defect marked by a special gap.

The system uses the indication of distance at each control field to know when to begin to disregard the information being read by the transducer head. Information read is invalid until a skip displacement value of 0 is read, meaning data should be regarded as valid information again.

Harder, Better, Faster, Stronger

Modern HDDs can now store vast quantities of data, with some drives, offered by the likes of Western Digital and Seagate, having a capacity of over 20 Tb. US Patent 4,568,988, with an effective filing date of 22 February 1984, is said to be the first disclosing the 3.5-inch form factor now standard within the industry. The application contains figures resembling something recognisable as a component of a modern personal computer, and is cited in other patents belonging to IBM and Hitachi.

The patent claims “a computer disk drive system comprising: at least one micro hard-disk having a diameter of between 85 and 100 millimeters …; transducer means for writing digital information on and reading digital information from said micro hard-disk in a format so that said micro hard-disk has digital information stored at a density of approximately 600 concentric tracks per inch; …”.

Compared to the 24-inch diameter disks of the IBM RAMAC 350, the size of the disks, also referred to as platters, had reduced considerably to a diameter between 8.5 and 10 centimetres. This increase in capacity and reduction in size may be attributed to the developments in the technology over time, including those discussed above (and throughout my other articles), advancements in materials, increased demand for affordable personal computing and increased capability in the production of

smaller-scale devices.

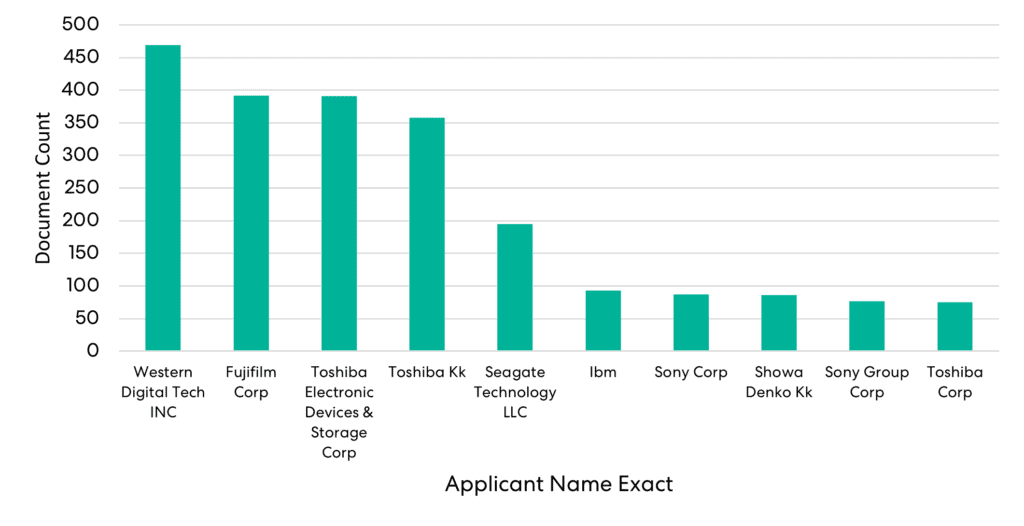

In the last 3 years (between the beginning of 2020 and 2023), and over 60 years since IBM’s ground-breaking RAMAC 350 system, the players in the HDD technology space have shifted again, and contain some recognisable modern market leaders. Again, in keeping with my previous articles, the chart below summarises the number of magnetic storage device-related patent applications filed by each named company, now between 2020 and 2023. Lens Patent Search was used to identify applications falling under IPC codes G11B 5/00 and G11B 11/00, relating to magnetic storage devices.

Western Digital (the new top filer), Toshiba and Seagate all feature on the chart above, and are household names in the field of Hard Drives and other modern types of computing storage devices. These three companies now represent the largest manufacturers existing today. Interestingly, the hard drive technology divisions of companies seen amongst the top filers in my previous articles were, through various business agreements, obtained by the likes of Western Digital, Seagate and Toshiba. Maybe surprisingly, IBM can be seen as the 6th top filer in this time period, showing how the company has maintained a strong focus on this technology for over half a century.

If nothing else, the filing statistics paint a picture of how the number of applications in the technology space has grown over time.

Where to?

It is evident that HDD technology has advanced substantially in the last 60 years from large, desk-sized systems to smaller drives commonly found in laptops and home PCs – such that they may be mistakenly thrown out alongside holey socks and pizza boxes. In 2021, following a joint development program, Toshiba and SDK announced technology allowing a reduction in the width of recording tracks on each disk platter, paving the way for future Hard Drives of capacities of 30Tb and above.

Beyond HDDs, the next step in the storage device evolution is Solid-State storage. These electronic, transistor-based devices are most commonly found in smaller, handheld devices such as mobile phones, with no moving parts. Nowadays, these devices have advanced such that they can rival the storage capabilities of some Hard Drives, and can be found in large-scale computing solutions as means of accessing data more quickly and eliminating mechanical delay.

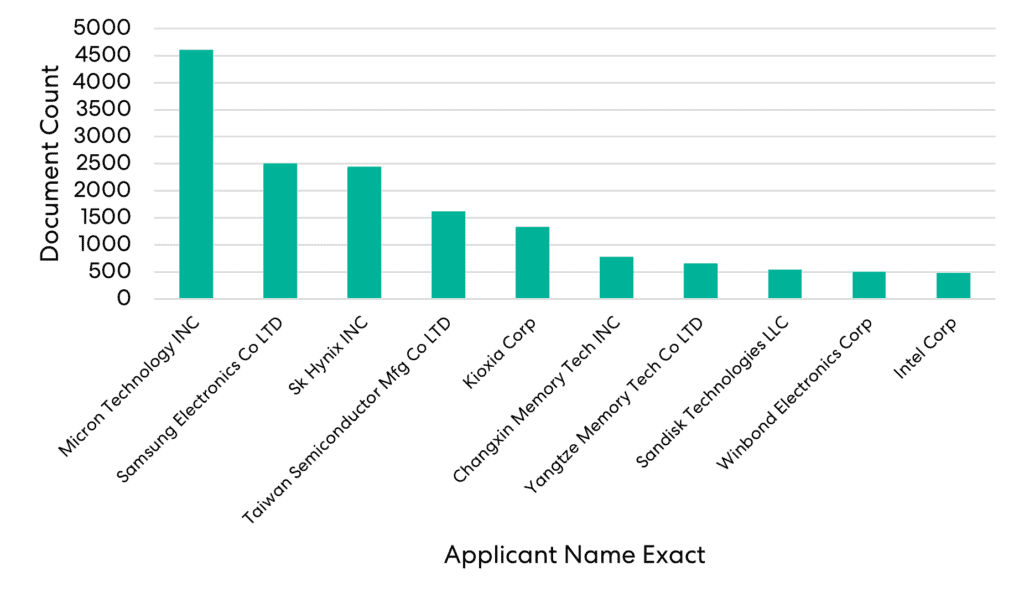

Top filers in the Solid-State storage industry within the last 3 years (the same 2020 to 2023 period as above) can also be found using a search for applications falling under IPC code G11C. The results below show Micron, a market leader in Solid-State manufacturing, as the top filer, and other large players such as Samsung, SK Hynix, and Taiwan Semiconductor.

Notably, the number of applications filed by Micron relating to Solid-State technology is over 10 times that of the number of applications filed by Western Digital relating to magnetic storage technology – an indication of where innovation is currently focussed. Even as the technology evolves, the goal of reliable, high-capacity electronic storage remains, and who knows what the next evolutionary step in the storage device timeline could be?

This is for general information only and does not constitute legal advice. Should you require advice on this or any other topic then please contact hlk@hlk-ip.com or your usual HLK advisor.